GE Quartz – Wafer Chambers

Situation |

GE Quartz was a leading pure materials supplier into the Semiconductor Equipment market. As a raw material supplier, GEQ sold quartz raw material to a rough machining house, who sold to a parts fabricator, who sold to a subsystems vendor, who sold to the ultimate OEM. The end result was that in a typical $2MM piece of wafter fab equipment, GE may have only had $20K – $25K of contributed value. |

Approach |

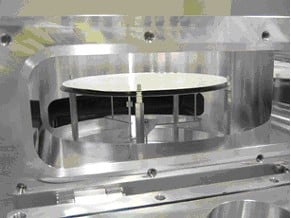

Through the acquisition of Advanced Ceramics Corporation, GEQ gained additional knowledge on construction of thermal components for wafer chambers. Jeff was well aware that GE as a corporation had a broad body of thermal modelling expertise at its Corporate Research and Development facilities. Through discussions with technical principals at several major semiconductor OEM’s Jeff learned that there was a trend in the industry for the OEM’s to want to outsource design and production of thermal submodules out to subcontracting supplier partners. Jeff put together a business plan and a strategy to forward integrate into the design and production of integrated wafer chambers which could be custom designed for a specific OEM application and produced to order. Jeff developed a Revenue Sharing Partnership relationship with an existing GEQ fabrication customer, who was already invested in clean rooom machining and assembly. GEQ recruited a technical design team with thermal modelers spread between India, Japan and the US and built a design and test facility in Kobe, Japan. |

Results |

GE commissioned the Kobe facility in July 2005. The facility embarked on a number of applications for leading OEM’s such as Applied Materials, ULVAC, and Hitachi-Kokusai. On average, the business was able to realize a 3X increase in the GE value participation of the ultimate equipment, and was able to deliver technically superior solutions via integrating the design and thermal modelling of all components in the wafer chamber.

|

GE Quartz – OEM Specifier Fee Partnership

Situation |

GE Quartz was a leading pure materials supplier into the Semiconductor Equipment market. As a raw material supplier, GEQ sold quartz raw material through a multilevel supply chain who ultimately delivered components to the end OEM. Although GE’s materials were specificied and called out on many of the drawings of the industry’s leading OEM, material on some key components was dual specified with competitive materials or not specified. Additionally, GE had limited ability to affect ultimate part cost for the OEM due to multiple levels of supply chain markup and pricing flexibility. GE lost many opportunities for it’s material to be pulled through for new equipment or spare parts sales due to this arrangement. |

Approach |

As the VP of Global Sales and Marketing for GE Quartz, Jeff and his commercial team “went around” the various levels of the supply chain and initiated a high level dialogue directly with the Product Management groups at the OEM. They developed a detailed plan to increase the specified GE content on the OEM’s equipment which had defined financial benefit for both parties. Jeff developed a “Specifier Fee” incentive structure where an incentive was developed for each component based on the amount of specified material content. This OEM incentive was delivered directly and was unknown and not dilluted by the supply chain. This enabled the OEM to continue to competitively bid parts through the supply chain while guaranteeing they would receive the benefits. |

Results |

Over a multi-year process, more than 100 components were re-specifed and revalidated in GE’s material, doubling GE’s market share at the OEM from 29% to 62%, and generating more than $8MM in incremental profitable revenue. |